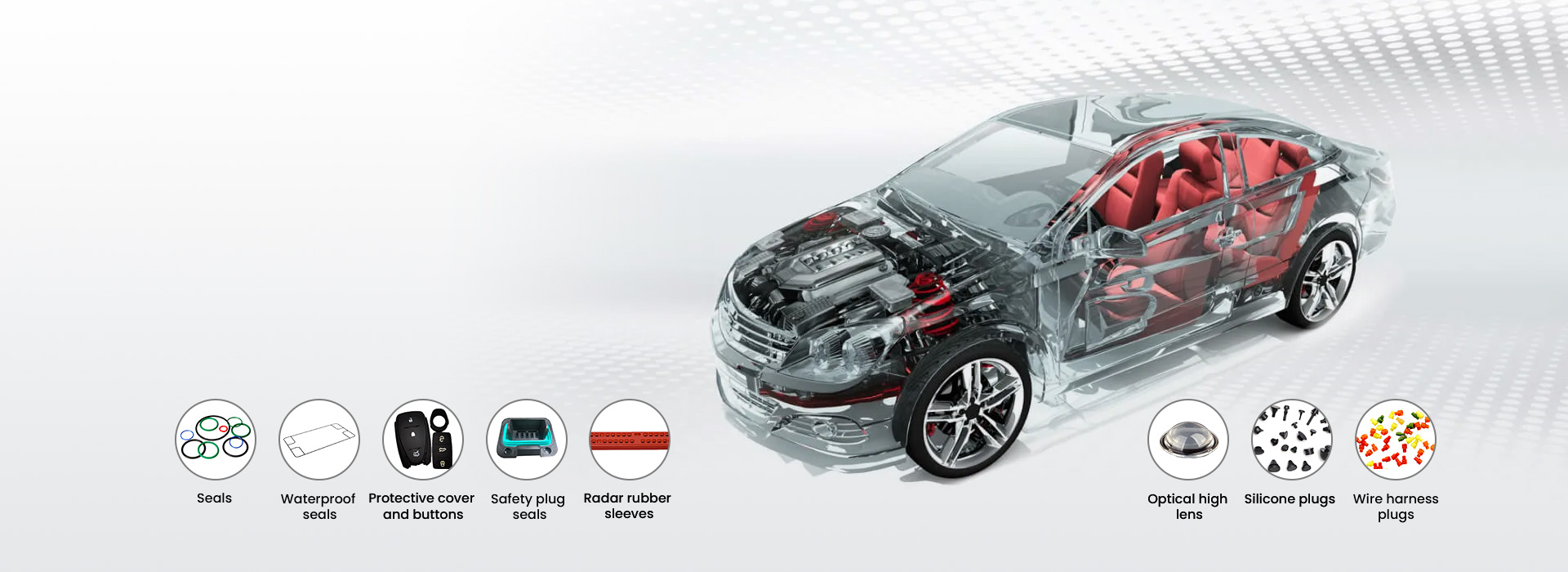

Soluciones de fabricación de sobremoldeo de silicona para diferentes industrias

Soluciones de fabricación de sobremoldeo de silicona

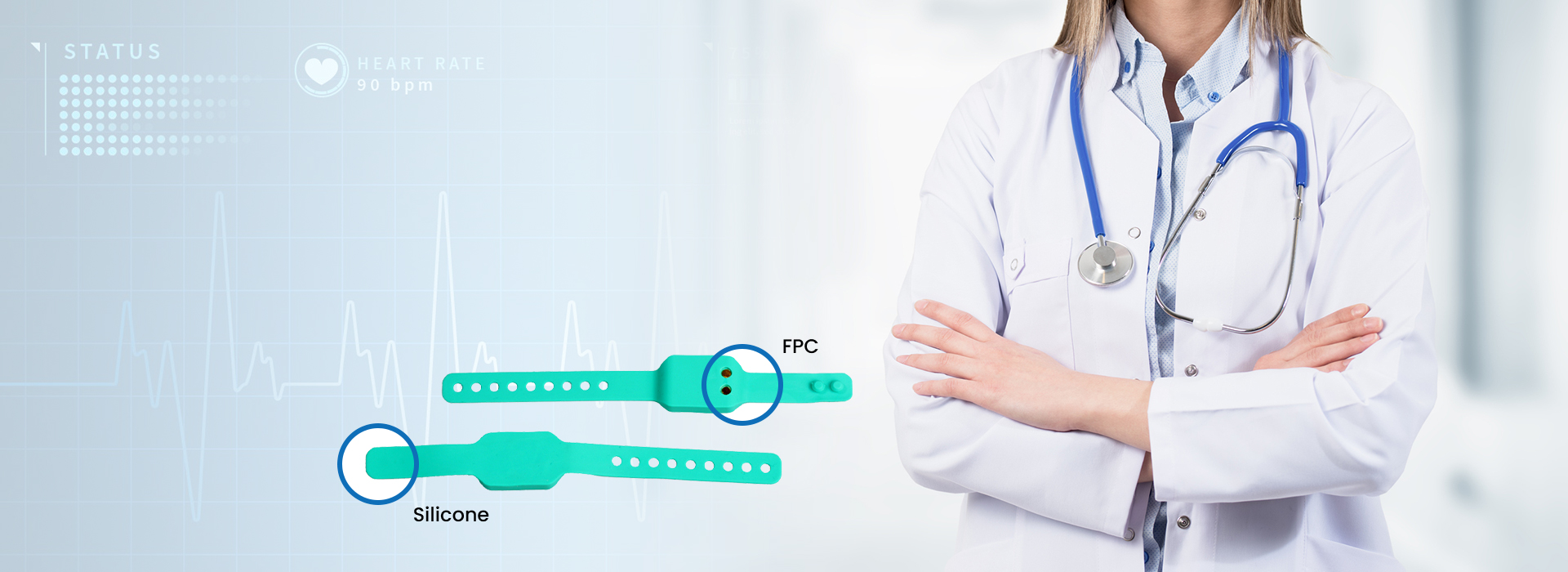

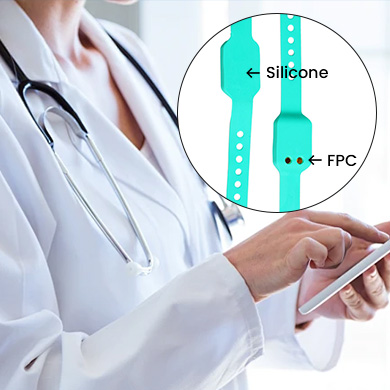

La silicona posee excelente flexibilidad, resistencia a altas temperaturas e impermeabilidad. Al combinarse con FPC, proporciona productos con mayor estabilidad y durabilidad.

La silicona líquida está moldeada con precisión, con un nivel de protección de hasta IP68, y es la primera opción para el sellado a prueba de agua en la industria electrónica.

El nuevo proceso de silicona en plástico combina perfectamente silicona y plástico para crear productos más fuertes, más duraderos y más flexibles.

Los materiales de silicona suaves y duraderos se envuelven entre sí para formar un material compuesto con múltiples propiedades excelentes.

Dale vida a tu visión: muestras gratuitas y servicio de consulta gratuito

Tengo un dibujo de diseño

- Proporcionar informe DFM

- Salida en 2 horas

- Haz la muestra en un plazo de 7 días.

Sólo tengo muestras reales

- Proporcionar medición y diseño

- Libre para el ajuste del molde

Solo tengo una idea

- Soporte tecnológico

- Diseño de dibujo

- Conviértase en idea de muestras

Modelo de Asociación Empresarial

Compañía comercial

- Silicona en alta demanda

- Servicio personalizado uno a uno

- Entrega rápida

- Servicio de cotización rápida y entrega de muestras

Fábricas que requieren servicios auxiliares

- Proporcionar piezas de silicona

- Proporcionar piezas de plástico

Solo tengo una idea

- Soporte tecnológico

- Diseño de dibujo de producto

- muestras entrega rápida

Proceso de fabricación por sobremoldeo de silicona

1

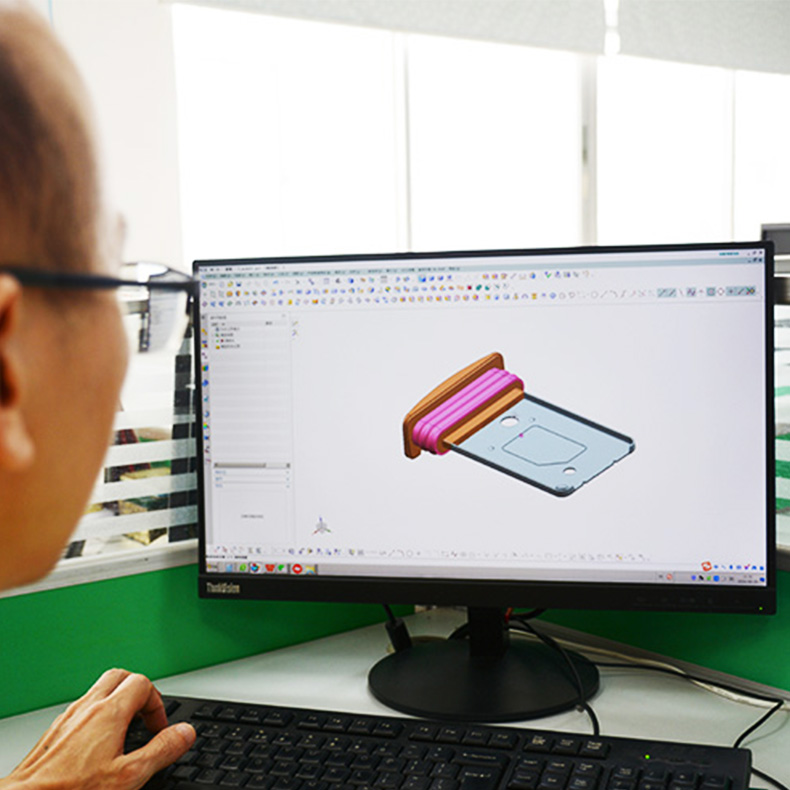

De acuerdo con las necesidades y requisitos del cliente, ofrecemos soluciones de diseño de productos innovadoras y prácticas. Nuestro equipo de diseño puede diseñar la solución más adecuada para usted y garantizar una presentación perfecta del diseño.

2

Contamos con nuestras propias capacidades de fabricación de moldes de silicona, equipados con equipos de alta gama y un equipo profesional, y estamos comprometidos a brindar a los clientes soluciones de moldes de silicona personalizados de alta calidad y alto rendimiento.

3

Ya sea que sus necesidades de productos de silicona sean de producción en masa o de personalización de lotes pequeños, podemos brindarle la mejor solución.

Capacidad de SiliconePlus

Somos líderes en la personalización de silicona, con 23 años de trayectoria. Reconocidos por nuestra especialización, eficiencia e innovación, nos comprometemos a fabricar productos integrados de silicona y otros materiales. Nuestra gama de productos es amplia e incluye soluciones personalizadas para silicona y FPC, metal, plástico, imanes y otras piezas estructurales de caucho de silicona. Para impermeabilización u otras necesidades, nuestros productos cumplen con el estándar IP67, el más alto de la industria. En la fabricación, utilizamos un exclusivo proceso de moldeo integrado de sólido a líquido, que ofrece claras ventajas en el coste del molde en comparación con el moldeo por inyección de silicona líquida común. Además, nuestro proceso es más flexible, lo que permite la producción personalizada de una sola pieza. Nuestro equipo está compuesto por profesionales experimentados y cualificados, como ingenieros de diseño de moldes de silicona, técnicos de mecanizado CNC e ingenieros de depuración de moldes. Cuentan con una amplia experiencia y un profundo conocimiento en la fabricación de moldes de silicona para ofrecer servicios personalizados de alta calidad.

Experiencia

23 años de fábrica de personalización de silicona

Reputación

La elección de clientes como OPPO, Luxshare, ZARA, etc.

Tecnología

Moldeo de una sola pieza de silicona + otros materiales

Nivel de impermeabilidad

El nivel más alto de impermeabilidad es IP67

Costo

Ventaja de costo del molde de moldeo de una sola pieza

Personalización

Producción flexible, se puede personalizar una pieza.

Casos de clientes

OPPO

Anillo de silicona impermeable para cámara elevadora

El recubrimiento de silicona del producto de OPPO representa el primer proyecto de impermeabilidad para la cámara de elevación de teléfonos móviles de alta gama. El reto consistía en lograr un alto nivel de impermeabilidad mediante el recubrimiento de silicona en productos galvanizados pulidos mediante pulvimetalurgia, conservando al mismo tiempo la apariencia impecable del producto. La competencia finalmente se dio por vencida debido a la complejidad, pero nosotros mantuvimos nuestro compromiso y superamos con éxito las barreras técnicas. Como resultado, conseguimos el 90 % de los pedidos y elevamos el estándar de impermeabilidad para productos 3C de IP65 a IP67. Este logro no solo demostró nuestra experiencia, sino que también estableció un nuevo referente en la industria para futuras innovaciones.

HFY

Nuevo parche de monitorización de ECG

HFY necesitaba desarrollar un nuevo parche para monitorización de ECG. Seleccionamos silicona de alta suavidad de grado médico, que cumple con los estándares médicos y es flexible y cómoda. Trabajamos con proveedores para personalizar el FPC de alta conductividad y desarrollamos un proceso especial de moldeo por inyección. Tras múltiples pruebas, ajustamos y optimizamos los parámetros para garantizar que la silicona cubriera perfectamente el FPC sin burbujas ni delaminación. El producto tuvo una excelente acogida entre médicos y pacientes y logró un excelente rendimiento de ventas.

Problema de impermeabilización

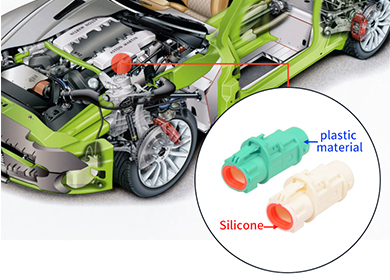

Conector automotriz impermeable

A medida que se desarrollan los vehículos de nueva energía, la impermeabilidad de los conectores es vital. Un fabricante experimentó fallos en los circuitos en condiciones de humedad debido a una impermeabilidad deficiente, lo que afectó la seguridad.

Cuestiones clave:

Impermeabilización insuficiente: Los conectores se cortocircuitan en ambientes húmedos.

Durabilidad: Estabilidad requerida en condiciones extremas.

Personalización: Los modelos complejos necesitan soluciones personalizadas.

Nuestra solución:

Impermeabilización eficiente: silicona de alta calidad que cumple con los estándares IP68.

Durabilidad mejorada: probado para entornos extremos.

Producción a medida: Diseñada para necesidades específicas, garantizando calidad y eficiencia.

Estuche de silicona para procesamiento de belleza y cuidado de la salud

Resolver las necesidades de los clientes y mejorar la competitividad del producto.

Con el desarrollo de la industria de la belleza y la salud, la demanda de productos de alta calidad, seguros y estéticos sigue en aumento. Una reconocida marca de belleza se enfrentó a un problema al desarrollar equipos de belleza de alta gama: necesitaba una carcasa de silicona suave y duradera que no irritara la piel, a la vez que garantizara una apariencia de alta gama y propiedades antibacterianas. Sin embargo, no había encontrado un proveedor adecuado. Utilizamos silicona de grado médico de alta gama para garantizar suavidad, no toxicidad y propiedades antibacterianas. Mediante el diseño y procesamiento de moldes de precisión, garantizamos que el producto cumpla con los requisitos de apariencia de alta gama y sea duradero. Entregamos a tiempo y brindamos soporte técnico de seguimiento para satisfacer las necesidades del cliente.

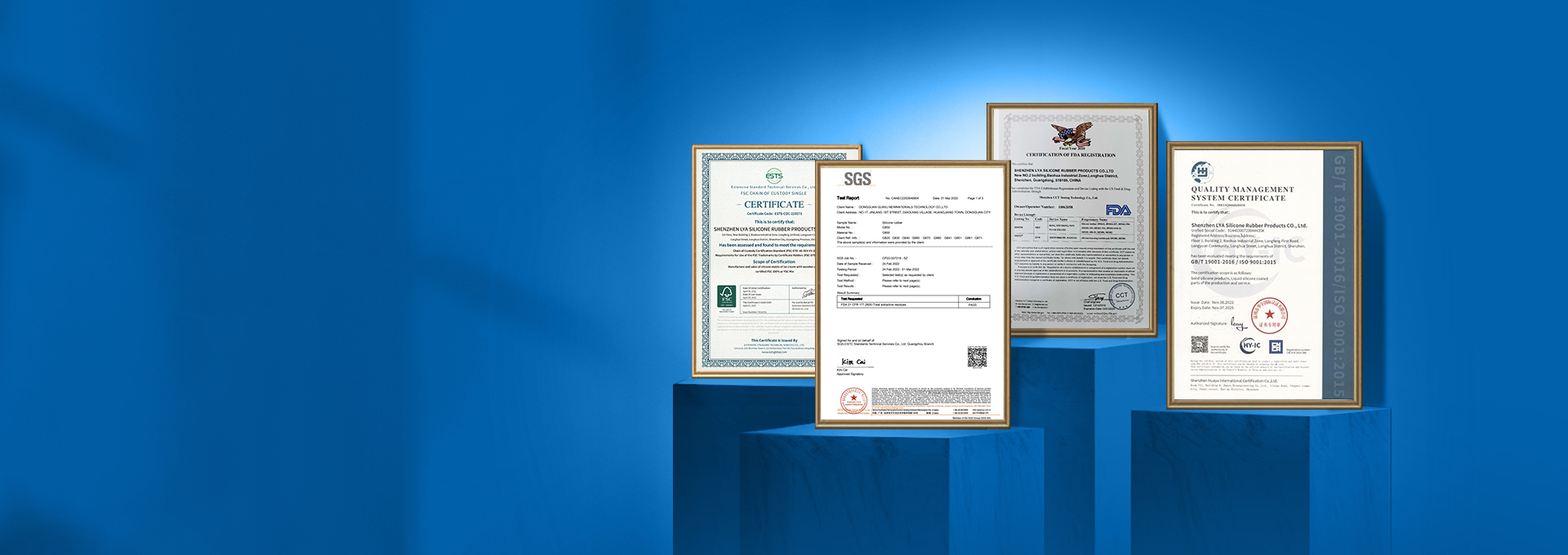

Con la confianza de más de 3000 clientes globales

Cualificaciones y honores

Nuestros socios

Adquisición de moldes y muestras

Nuestro servicio de atención al cliente está online 24 horas al día, 7 días a la semana para brindarle asesoramiento profesional.

- Prototipo rápido

- Servicio de consulta gratuito

- Muestras similares gratuitas para referencia

- Informe del DFM

Análisis de requisitos y soluciones

Según sus necesidades específicas y los requisitos del proyecto, le brindaremos soluciones personalizadas para satisfacer mejor sus necesidades.

Informe DFM gratuitoCotización rápida

Contáctenos para brindarle rápidamente mejores prototipos de productos de silicona y plástico.

Cotización rápida

- nombre completo:

- Miss Yang

- Teléfono:

+86-13420974883

- Email:

- sale11@lyasilicone.com

- WhatsApp:

- 8613424186971

- Skype:

- 8613420974883